Capabilities

Davis Tool & Die is your preferred source to design and build dies

Home »

Turn to Davis Tool & Die as your preferred source to design and build

Davis Tool & Die is where the die cast industry in North America turns for outstanding tooling design of hot and cold chamber aluminum, zinc, and magnesium dies.

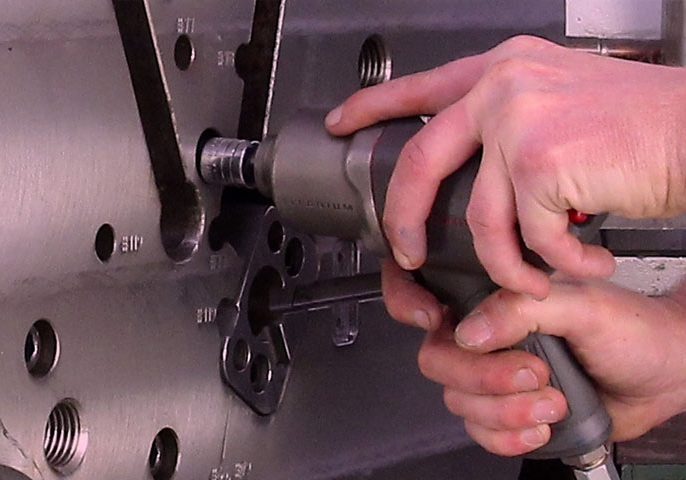

Depend on Davis Tool & Die for cavity replacement, major mold base rebuilds and other die restoration services. We assure a quick turnaround time as a normal part of the way we do business.

For vertical, tilt bed or horizontal presses. Positive knock out or spring loaded ejection, push through and dump pans with mechanical actuation from the press cycle.

Machine castings for prototypes, pilot runs or pre-production machining runs from a solid piece of aluminum, magnesium, or zinc using the 3-D CAD Model.

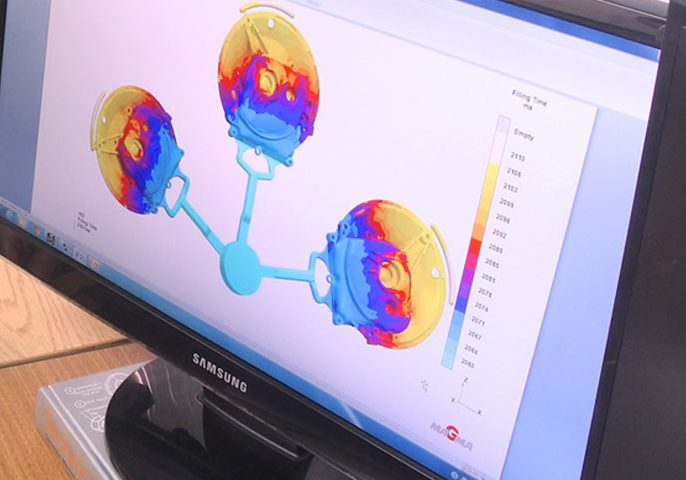

Davis Tool & Die engineers provide professional support for the design of your dies for the most efficient production using MAGMA software and FEA software.

We build dies that run in die casting machines with a capacities from 300 tons up to 2,500 tons of locking force on hardened cavity blocks and electrodes on our 20 CNC Milling Machines.

Davis Tool and Die offers the North American die casting industry our large 43,000 square foot capacity die making and repair center conveniently located in the Midwest.

Production becomes easier with high repeatability dies delivered on time and backed by outstanding after sale service from Davis Tool & Die, an ISO 9001:2000 and AS9100 Certified company.