Why Precision Matters: How Our Advanced Engineering Delivers Reliable Production

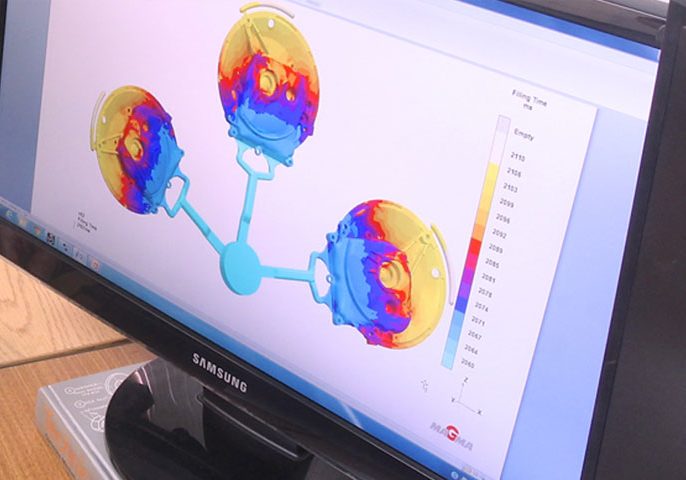

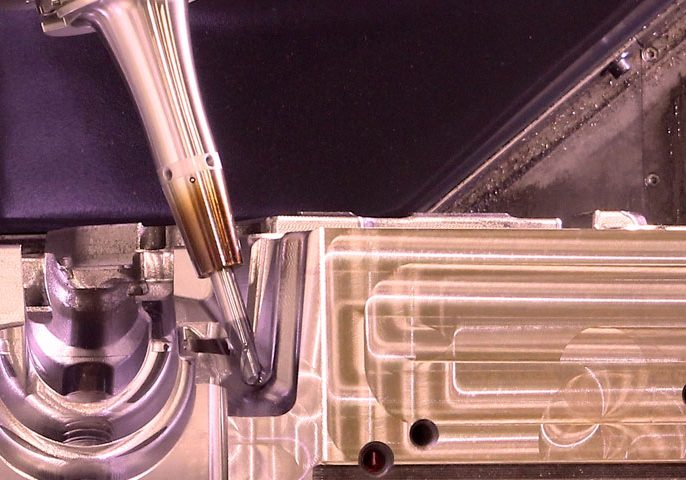

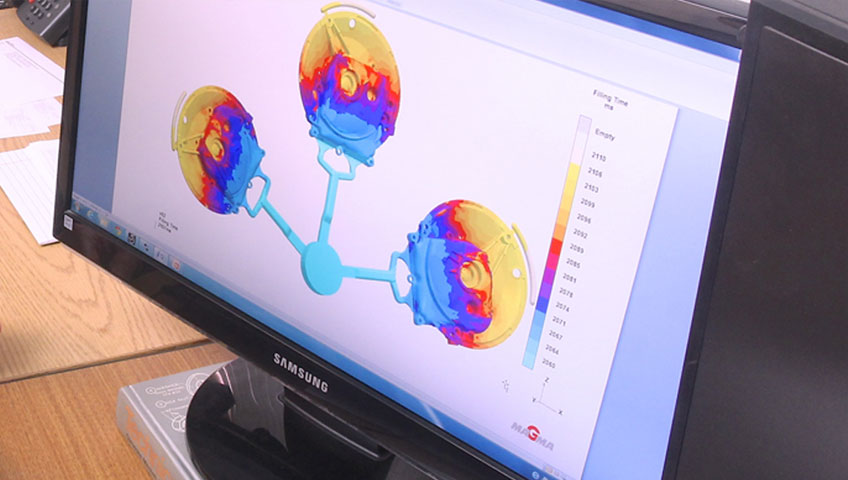

In manufacturing, even small tolerances can impact product quality. At Davis Tool & Die, precision is one of our highest priorities. Our in house engineering team has decades of experience and uses advanced tools such as 3D CAD modeling and flow and thermal simulation software to design dies that consistently hold tight tolerances.

Our capabilities include the design and build of new dies, trim dies, prototypes, and the refurbishment of existing molds. This range of services gives our customers flexibility for prototyping, pre production, and full scale manufacturing.

For companies in die casting, plastic injection molding, aerospace, and many other industries, our focus on precision supports consistent production performance. It also helps reduce downtime, lower defect rates, and speed up time to market.